3/8/21

Announced during WTW21 press conference.

Mack Trucks WTW21 exhibitor listing

Mack® MD Series Exceeds Customers’ Expectations as Orders, Interest Grows

Mack Trucks’ MD Series models are exceeding customer and dealer expectations for productivity and performance, resulting in strong order activity and driving increased interest in the medium-duty vehicles.

“Mack is proud that customers and dealers are excited about our new Mack® MD Series,” said Jonathan Randall, Mack Trucks senior vice president of North American sales and commercial operations. “We knew the product had potential for strong market acceptance, and the initial reception and response confirms our confidence. With the addition of the MD6 and MD7 vehicles, Mack now offers a complete lineup of Class 6 to Class 8 vehicles to meet customer requirements.”

Mack launched the Mack MD Series Jan. 30, 2020 at its Roanoke Valley Operations (RVO) facility in the Roanoke Valley, Virginia, where the Mack MD Series is assembled. Mack first publicly showed the vehicles during the 2020 Work Truck Show.

“The launch of the Mack MD Series was the most impressive product launch ever by Mack,” said John Schwind, general manager and director of medium-duty trucks for Nextran Truck Centers, Fort Myers, Florida. “The chassis is lighter, but with a Class 8 cab and frame so it’s durable and sound. It’s also equipped with proven technology, offering the best solution in the segment.”

The Mack MD Series includes the MD6, a Class 6 model with a Gross Vehicle Weight Rating (GVWR) of 25,995 pounds, and the MD7, a Class 7 model with a GVWR of 33,000 pounds. Both models are exempt from the 12 percent Federal Excise Tax (FET).

“The first two Mack MD trucks that we received, driven by the first two customers, were purchased within the first hour of us receiving them,” Schwind said.

United Site Services, the nation’s leading provider of portable sanitation and temporary site solutions with more than 120 locations coast to coast, recently purchased 137 Mack MD6 vehicles from Bergey’s Truck Centers, Pennsauken, New Jersey. United Site Services, based in Westborough, Massachusetts, has about 2,500 vehicles in its fleet, 75 percent of which are medium-duty vehicles.

“Mack has a tremendous history dating back to World War I, and the Mack Bulldog on the Mack MD6 signifies the truck’s durability and reliability,” said Kevin Podmore, vice president of fleet and strategic sourcing, United Site Services. “Our medium-duty trucks need to be able to handle a broad range of environments, and we believe Mack’s reliability will enable us to see incredible results.”

Available in 4x2 configurations, the Mack MD6 and MD7 are ideal for dry van/refrigerated, tank truck, dump, stake and flatbed applications. The MD Series also offers a clear back of cab and top of frame rail to make it easier for body builder adaptations. It’s this versatility that customers appreciate, said Steve Rybacki, director of medium-duty trucks for Bergey’s.

“There’s been a lot of excitement about this product, both internally and with customers,” Rybacki said. “The Mack MD offers great flexibility and an accommodating clean frame option, allowing for a wide variety of body upfitting opportunities. This feature has made it a perfect fit for customers such as United Site Services.”

“We decided to order the Mack MD6 because, with features like the large windshield and maneuverability, we believed Mack could handle our range of applications from pumping water and waste, plus running numerous PTO outputs on the truck,” Podmore said. “All of this factors into the safety of our drivers and reliability of service for our customers, which ultimately drive our success. We also have a history with Mack heavy-duty products, so we know Mack’s durability.”

A Commercial Driver’s License (CDL) is not required to operate the MD6 model as long as the payload is non-hazardous. The MD6 and MD7 models are equipped with the Cummins B6.7 engine, an Allison six-speed transmission and Meritor front and rear axles.

The Mack MD Series models feature a sharp wheel cut for increased maneuverability in tough to navigate urban settings, as well as an industry-best 103-inch bumper-to-back-of-cab (BBC) measurement. The driver-focused interior of the Mack MD6 and MD7 models shares comfort and ergonomic design features with Mack’s Class 8 truck models, ensuring a quiet ride for drivers. The exterior of the medium-duty models was inspired by the Mack Anthem®, Mack’s highway model, matching its bold look and styling in the grille and hood design.

Eight wheelbase lengths are offered with the Mack MD Series, supporting typical bodies ranging from 10 to 26 feet. The vehicles come standard with 22.5-inch wheels or optional 19.5-inch wheels.

Bruckner Truck Sales in Lubbock, Texas, currently has 180 Mack MD models on order and sees the vehicles as a strong opportunity for their leasing fleet.

“The Mack MD is still built like a Mack truck, and it’s offered with a proven powertrain, probably the best combination for Class 6 and Class 7 trucks, so there are no questions and no hurdles to overcome,” said Cobe Gilliam, truck sales representative at Bruckner’s. “This is one of the best new product introductions we’ve seen, and it’s one we welcomed with open arms. It’s one of the easier products to sell.”

Teinert Metals, Inc., a family owned and operated steel supplier based in Lubbock, is Bruckner’s first customer to receive the Mack MD6 truck. Teinert operates 18 trucks in its fleet and ordered the MD6 because of the positive experience the company had with the two Mack Anthem models it operates.

“It’s pretty special that we received Bruckner’s first MD truck,” said Logan Teinert, fleet manager of Teinert Metals. “The truck rides very nicely. It looks sharp, and is well built and durable. Immediately, we received several compliments on it out in the field. Our drivers are very excited about running it.”

The Mack MD Series will be supported through Geotab Go, offering access to Mack OneCall™ agents, available 24/7 at the Mack Uptime Center based in Greensboro, North Carolina.

Pictured on the left is Logan Teinert, fleet manager of Teinert Metals (left), and Randy Teinert, owner (right), who stand beside their first Mack® MD6, one of two in their fleet. The Mack MD6 pictured on the right is part of the leasing and rental fleet owned by Mack dealer TranSource Truck & Trailer Centers in Greensboro, North Carolina.

Pictured on the left is Logan Teinert, fleet manager of Teinert Metals (left), and Randy Teinert, owner (right), who stand beside their first Mack® MD6, one of two in their fleet. The Mack MD6 pictured on the right is part of the leasing and rental fleet owned by Mack dealer TranSource Truck & Trailer Centers in Greensboro, North Carolina.

Mack® Command Steer for Mack Granite® Models Now in Production

Mack® Command Steer, Mack’s highly anticipated active steering system that reduces driver fatigue, is now in production in Mack Granite® axle back models. Produced at Mack’s Lehigh Valley Operations (LVO) facility in Macungie, Pennsylvania, where all Mack Class 8 models for North America and export are assembled, Mack Granite models with Command Steer help reduce the physical demands of working on a jobsite. “Driving a heavy-duty construction truck is physically demanding on the body,” said Tim Wrinkle, Mack construction product manager. “Jobsites have uneven road conditions, which contribute to wear and tear on the driver. Mack Command Steer has been shown to reduce driver effort by 85 percent, improving jobsite safety and driver productivity.”

Mack Command Steer combines an electric motor with the Mack Granite model’s existing hydraulic steering. Multiple sensors throughout the truck monitor the terrain, driver inputs and environmental elements more than 2,000 times per second. Based on the collected data, the system provides variable steering effort through its electric motor, applying additional torque as needed to make it easier to keep the truck on the desired route.

Along with a significant reduction in driver steering efforts at slow speeds, Command Steer suppresses uneven terrain, such as potholes, dips and ruts. The system reacts to those irregularities by countering the steer force, smoothing the steering feedback and reducing steering wheel “kicks.”

“Drivers no longer need to fight the wheel when driving on severe terrain or during difficult weather conditions requiring a lot of steer effort,” Wrinkle said. “Mack Command Steer helps the driver maintain greater control of both on-highway and off-road applications at low speeds and high speeds.”

An additional benefit of Mack Command Steer is that the system features a unique return-to-zero capability that automatically returns the steering wheel to the center position in forward and reverse, helping to simplify tight maneuvers.

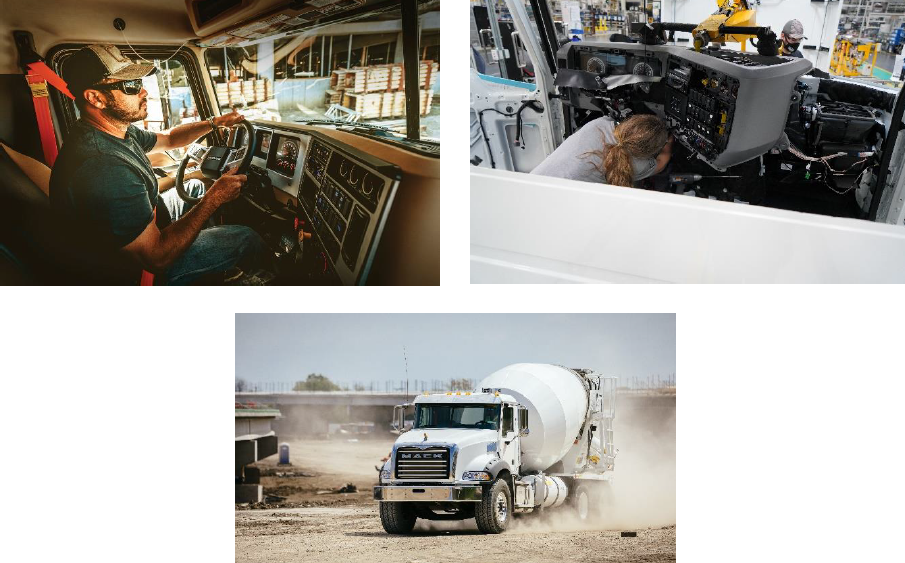

Pictured top right is the production line at Lehigh Valley Operations (LVO) in Macungie, Pennsylvania, where all Mack Class 8 vehicles are assembled. Pictured on the bottom is the Mack Granite model on a jobsite.

Pictured top right is the production line at Lehigh Valley Operations (LVO) in Macungie, Pennsylvania, where all Mack Class 8 vehicles are assembled. Pictured on the bottom is the Mack Granite model on a jobsite.

Mack® mRIDE™ Suspension Paired with Mack Axles Delivers Weight Savings, Increased Payload

The Mack® mRIDE™ spring leaf over rubber block suspension, ideal for vocational customers needing improved stability and greater traction on jobsites, now offers additional weight savings for increased payload when paired with proprietary Mack axles.

“Mack made these enhancements as a result of ongoing continuous improvement that is a hallmark of Mack’s product development,” said Tim Wrinkle, Mack construction product manager. “The Mack mRIDE already offers customers a smooth ride, and now when paired with our legendary Mack axles, it saves weight and reduces their total cost of ownership.”

Available at 40,000-pound and 46,000-pound suspension ratings and with standard track axles, customers can save 140 pounds with drum brakes and 146 pounds with air disc brakes as a result of casting suspension components into the Mack axle housing. Mack axles are produced at Mack’s powertrain facility in Hagerstown, Maryland.

The mRIDE’s parabolic springs are thickest at the center to ensure the clamp load area offers the greatest strength and are tapered to improve driver comfort. The mRIDE provides extreme articulation and constant tire contact, delivering superior traction on the rough terrain of jobsites.

The spring leaf design and V-shaped torque rods ensure stability to efficiently transmit forces into the truck’s frame. Shock absorbers, along with rubber and steel shock towers, improve ride and handling.

The mRIDE is fully integrated with Mack MP engines, transmissions and axles and can be spec’d in the Mack Pinnacle™ axle forward, Mack Granite®, Mack TerraPro™ and Mack LR. Mack also recently announced that it has enhanced its standard axle warranty for Model Year 2022 Mack models, extending time and mileage coverage. Mack vehicles available with the extended standard axle coverage include the Mack Anthem®, Pinnacle, Granite, TerraPro and LR models.

The Mack® mRIDE™ spring leaf over rubber block suspension, ideal for vocational customers needing improved stability and greater traction on jobsites, now offers customers additional weight savings allowing for increased payload when paired with proprietary Mack axles.

For more information, visit

macktrucks.com.

NTEA Member Directory listing for

Mack Trucks

View all news